Battery Recycling Statistics By Production, Prices, Usage And Demand

Updated · Sep 06, 2024

Table of Contents

- Introduction

- Editor’s Choice

- Global Production Of Battery Minerals

- Lithium End Usage Worldwide Usage

- Lithium-ion Battery Prices Worldwide

- Electric Vehicle Sales Worldwide

- Composition Of Lithium-ion Batteries In EV

- Lithium Carbonate Prices

- Mineral Battery EV Cost Vs Conventional Costs

- Mineral Content Of EV Lithium-Ion Batteries

- Lithium-Ion Battery Requirement By Region

- Demand For Selected Minerals For EV Production

- Rising Lithium Demand

- Rise Of Electric Vehicle Battery Recycling

- Worldwide Lithium-ion Battery Recycling Market Value

- Lithium Ion Battery Requirement By Segment

- Lithium Ion Reuse Future By Country

- Estimated Recovery Rate Of Battery Minerals

- Battery Recycling Material Availability

- Supply Of Electric Vehicle Batteries For Recycling

- Distribution Of EV Battery Recycling By Source

- Battery Recycling Overview

- Conclusion

Introduction

Battery Recycling Statistics: Battery recycling refers to activities that reduce the number of batteries usually disposed of as solid water. Batteries contain many heavy metals that, if not disposed of properly, would lead to soil contamination or water pollution. Likewise, industries have been developed that focus on ensuring environmental sustainability.

As we go forward, it is essential to go through the Battery Recycling Statistics and get information about the various ways businesses function.

Editor’s Choice

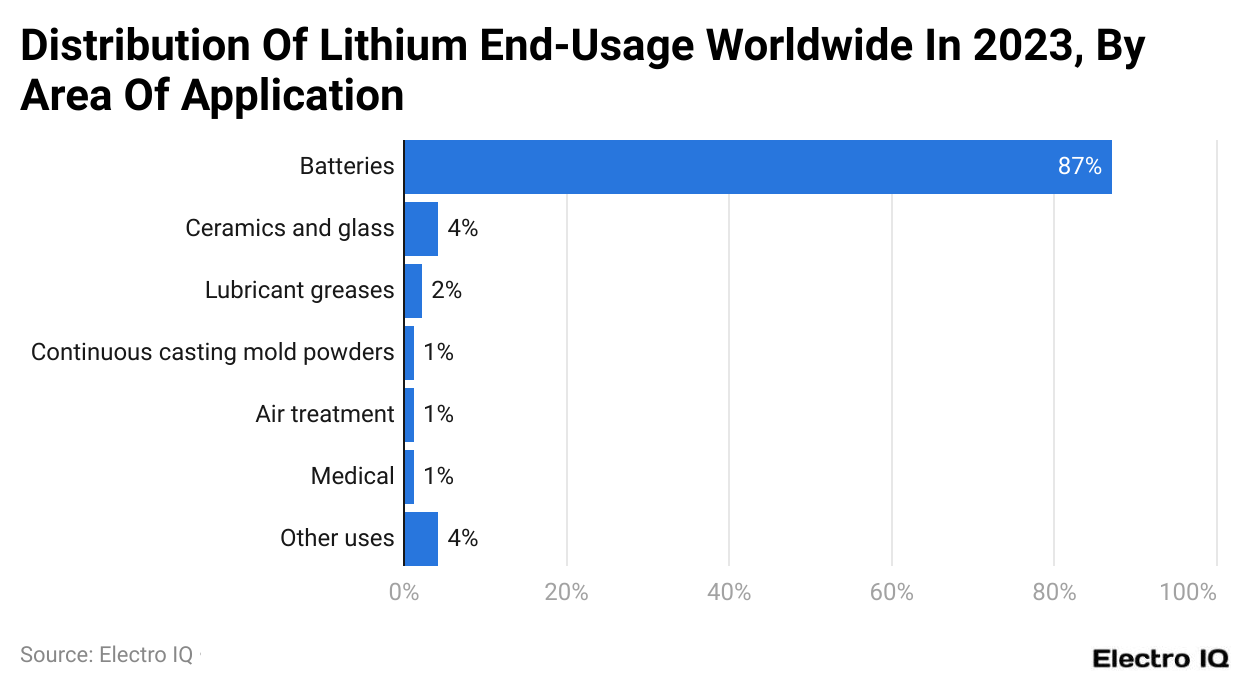

- Battery recycling statistics show that batteries comprise 87% of all lithium end usage worldwide.

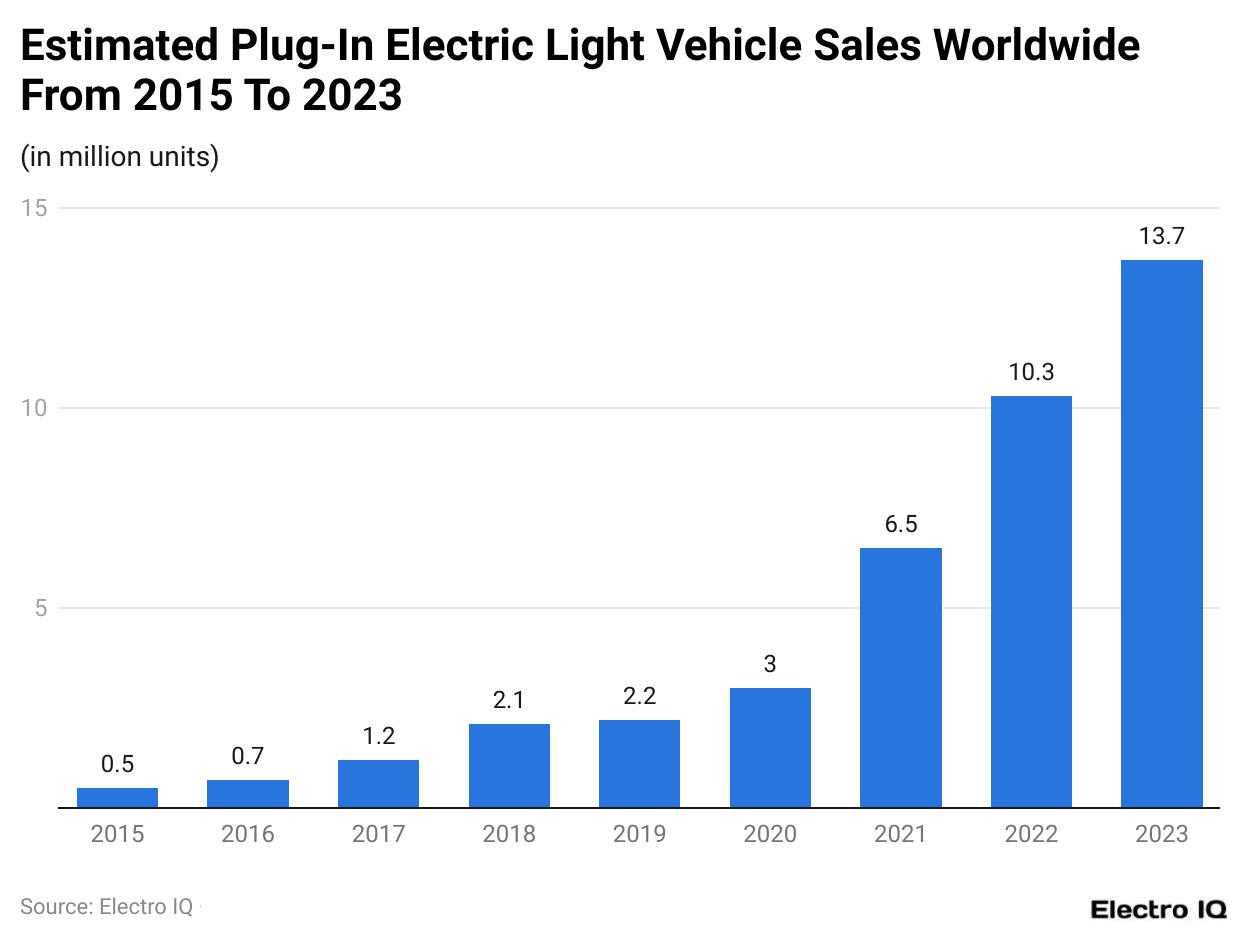

- Electric vehicle sales increased from 0.5 million in 2015 to 13.7 million in 2023.

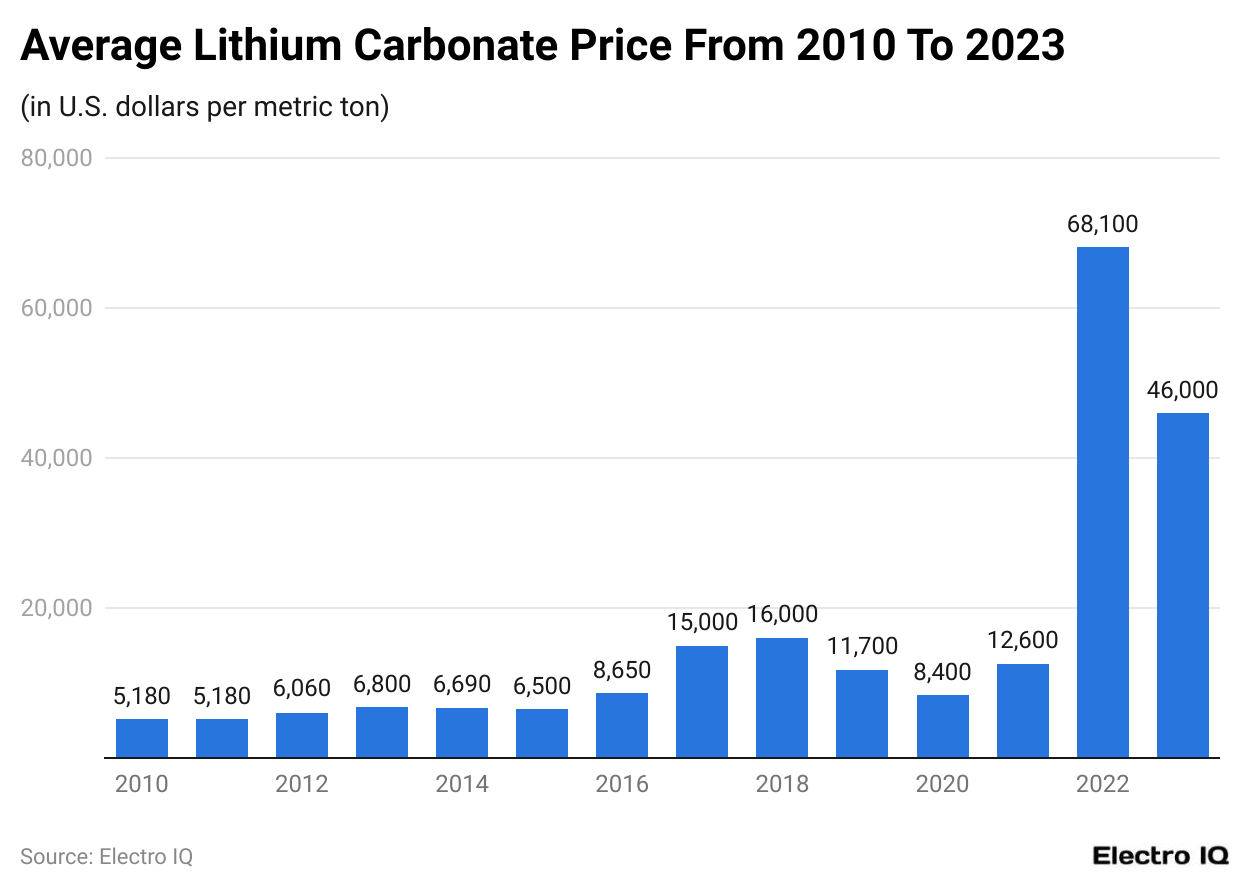

- The price of Lithium Carbonate in 2022 was USD 68,100 per metric ton in 2022.

- The global lithium demand in 2035 will be 3,829 metric tons by 2035.

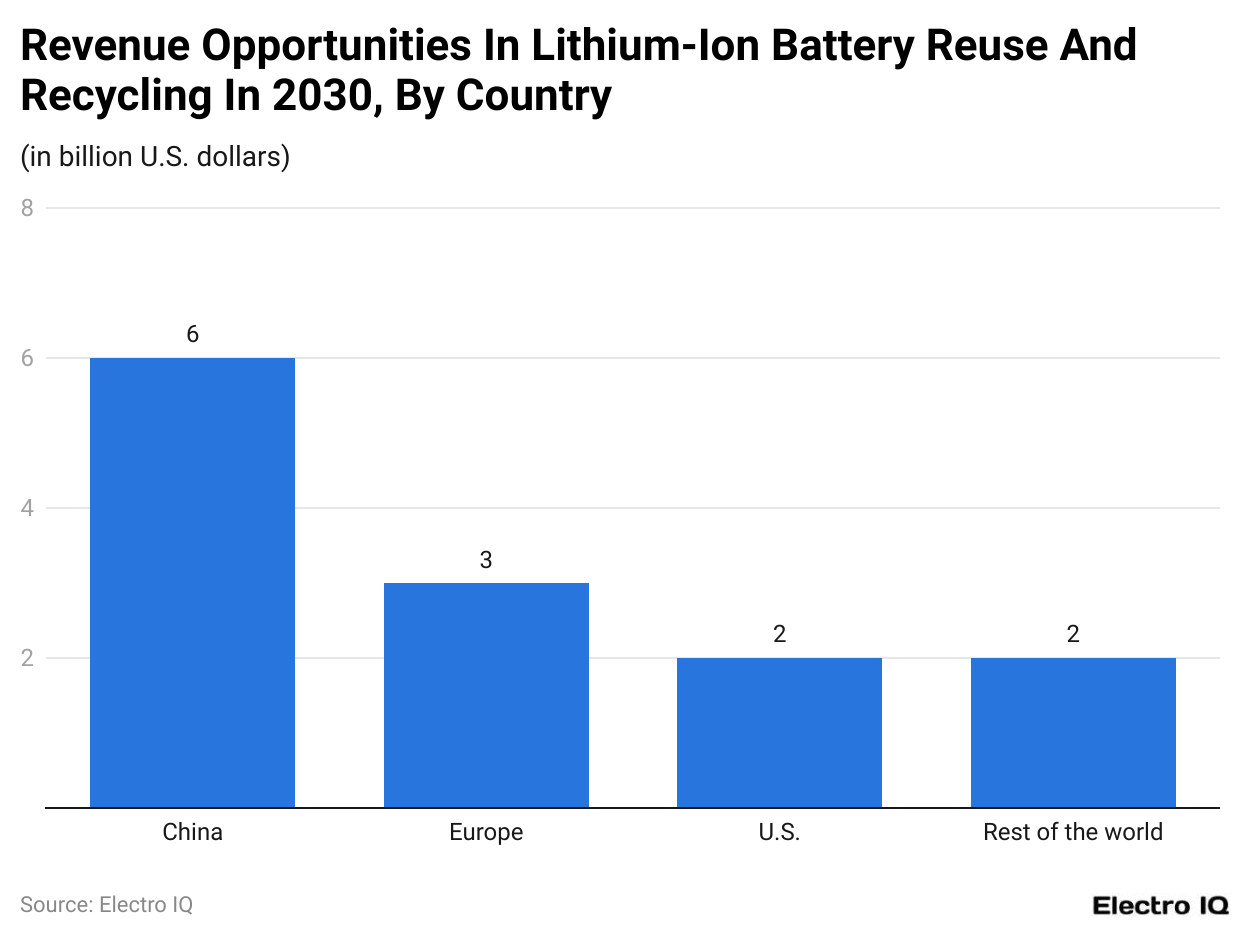

- China is expected to have USD 6 billion in revenue opportunities with lithium-ion usage by 2030.

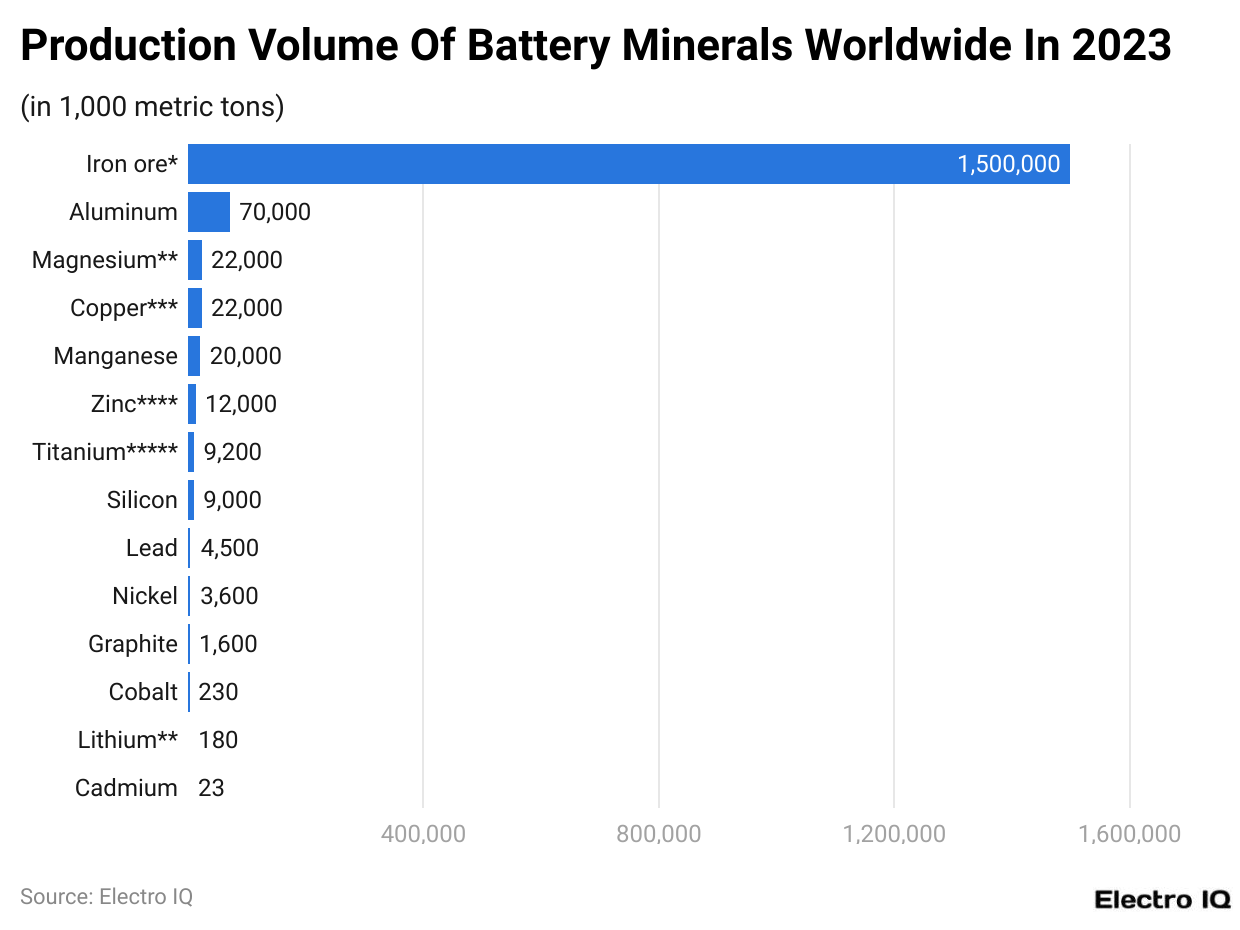

Global Production Of Battery Minerals

(Reference: Statista.com)

- Going through battery recycling statistics is crucial to garnering essential information about different battery minerals utilized for production.

- Iron ore is the most used battery mineral in production, producing 1,500 metric tons as of 2023.

- It is followed by Aluminum, Magnesium, Copper, Manganese, and Zinc, with 70 metric tons,22 metric tons, 22 metric tons, 20 metric tons and 12 metric tons.

Lithium End Usage Worldwide Usage

(Reference: Statista.com)

- The battery recycling statistics show that lithium end-usage with batteries by the area of application of lithium-ion end usage by application.

- As expected, batteries tend to have the highest lithium end-usage, with 87%.

- It is followed by Ceramics and glass, lubricant greases, mold powders, air treatment, medical and other uses with 4%, 2%, 1%,1%, 1%, 4%.

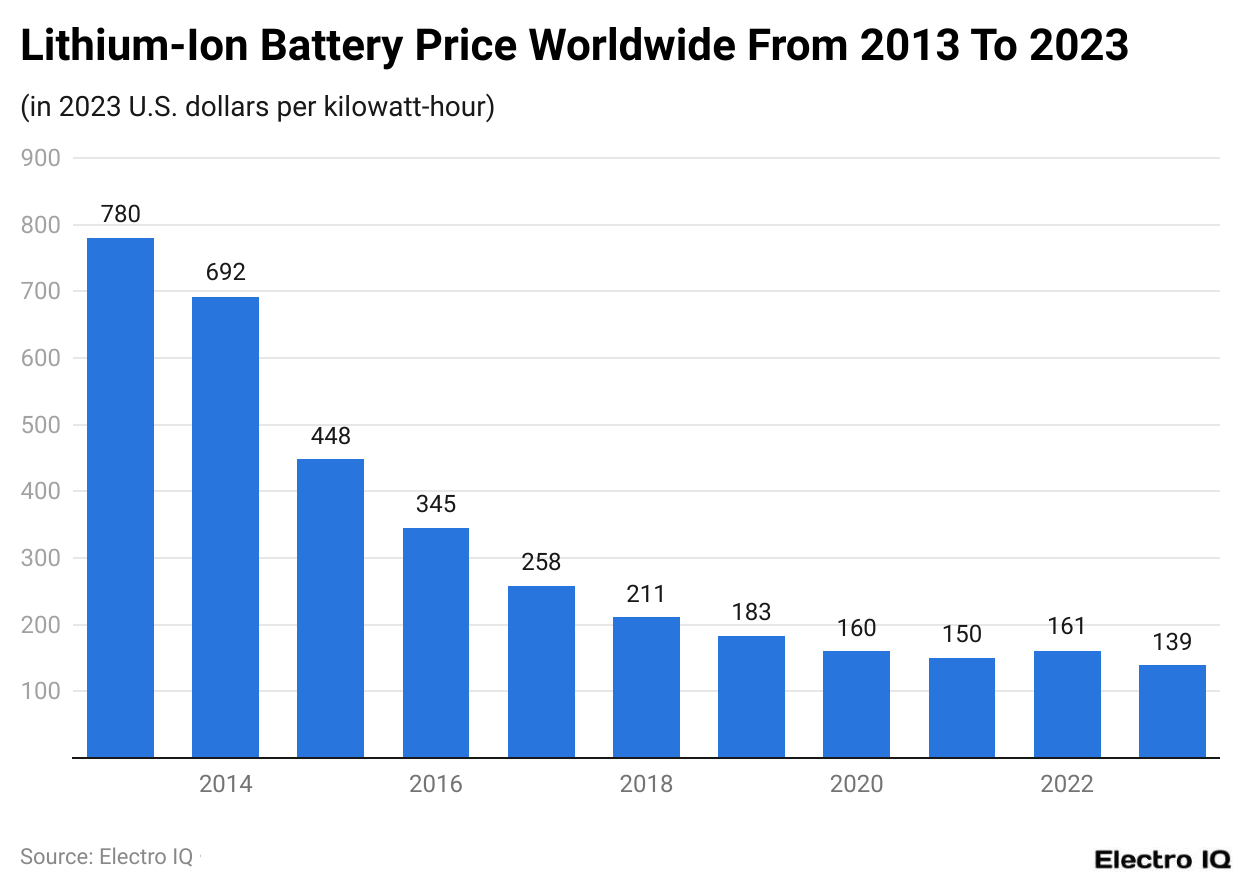

Lithium-ion Battery Prices Worldwide

(Reference: Statista.com)

- The battery recycling statistics show that the price of lithium-ion batteries has reduced significantly over time.

- In 2013, the price of a lithium-ion battery was $780 per kilowatt hour.

- By the next decade, in 2023, the price has significantly reduced to $139 per kilowatt hour.

- This showcases how the lithium-ion price reduction has led to a significant increase in usage of electronic devices.

Electric Vehicle Sales Worldwide

(Reference: Statista.com)

- Battery recycling statistics show lithium-ion batteries usually power electric vehicles.

- A reduction in the cost of lithium-ion batteries reduces the overall cost of electric vehicles, leading to high costs.

- While in 2015, the number of electric light vehicles was 0.5 million, it increased to 13.7 million sales by 2023.

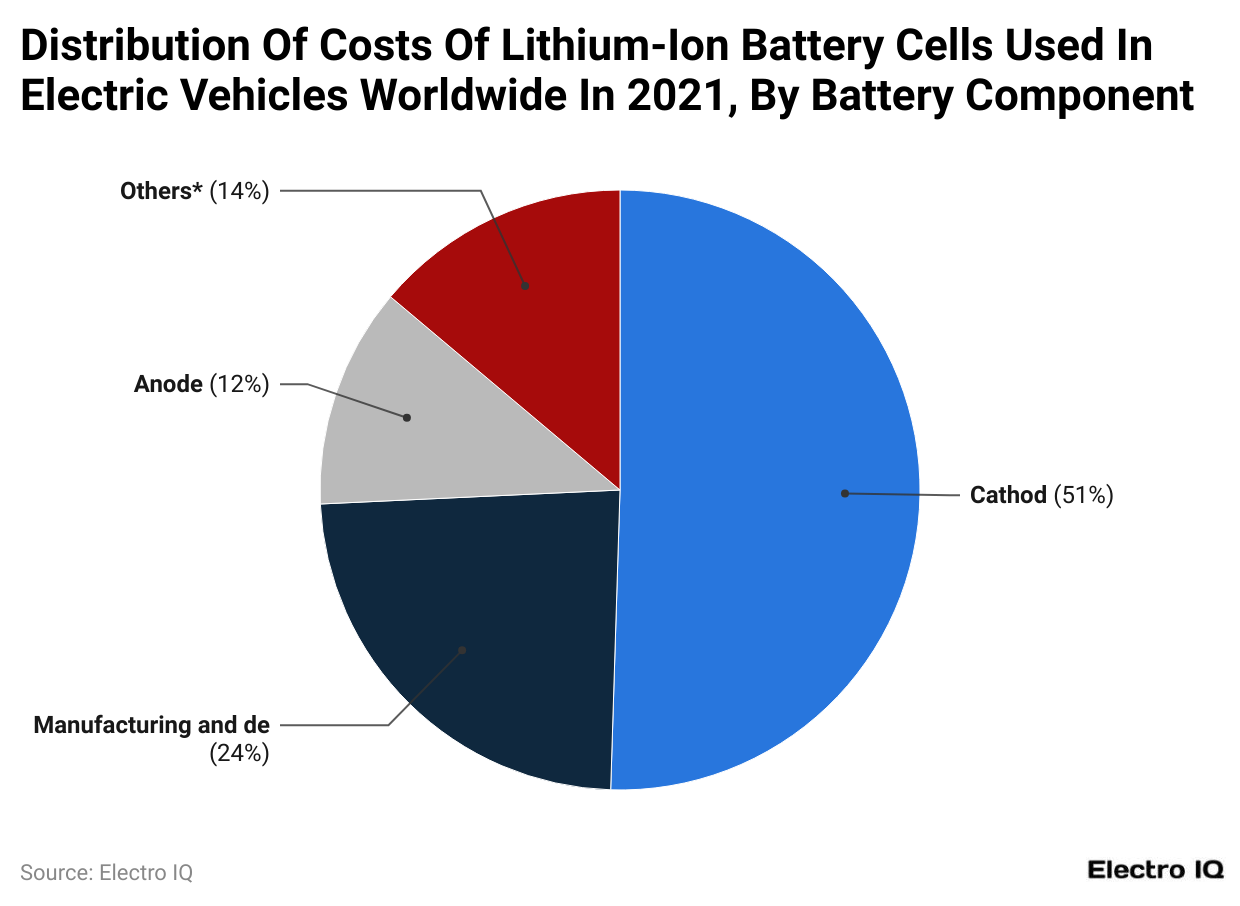

Composition Of Lithium-ion Batteries In EV

(Reference: Statista.com)

- Battery recycling statistics show that the overall composition of lithium-ion batteries in cars can be divided into the following segments: Cathode, Anode, Manufacturing devices, and remaining components.

- The cathode is the major component, with 51%, followed by manufacturing with 24%, then the anode component with 12%, and finally, the remaining products with 14%.

Lithium Carbonate Prices

(Reference: Statista.com)

- Lithium carbonate is an inorganic compound that comprises lithium salt and oxides. It is used as an industrial chemical.

- The battery recycling statistics reveal that lithium carbonate prices gradually increased till 2021.

- In 2022, there was a sudden spike in the cost of lithium carbonate at $68,100 per metric ton, which was significantly higher than the 2021 level, which was $12,600 per ton.

- By the end of 2023, the lithium carbonate cost is $46,000 per metric ton.

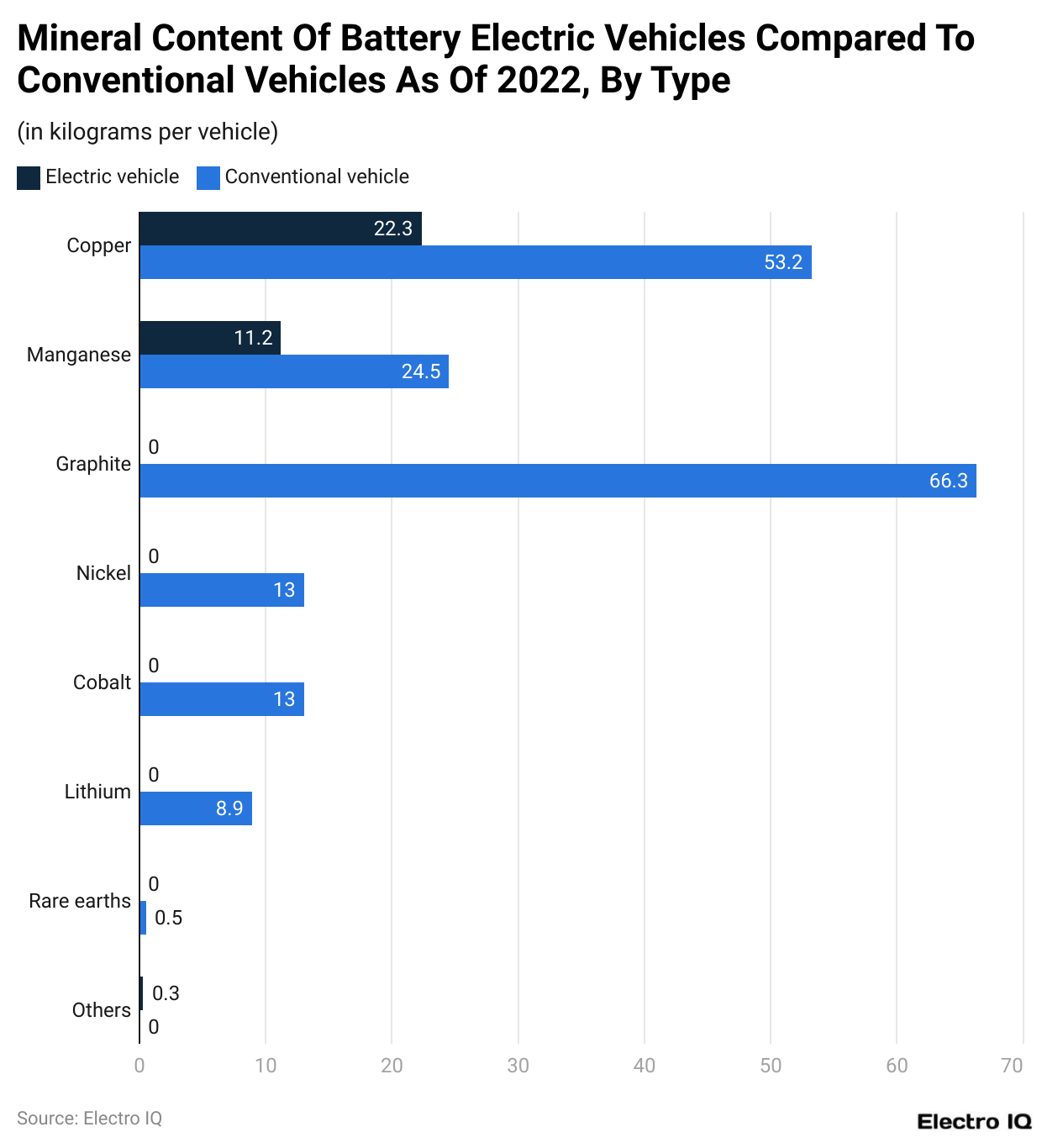

Mineral Battery EV Cost Vs Conventional Costs

(Reference: Statista.com)

- It is essential to review battery recycling statistics to obtain holistic information about the mineral content of batteries.

- Manganese and copper are the two elements present in both electric vehicles and conventional vehicles.

- The copper content in electric vehicles is 53.2 kg mineral content, and in comparison, there is 22.3 kg mineral content of copper content.

- It is interesting to know that electric and conventional vehicles have different manganese content. In the electric category, there was 5 kg per vehicle, while in conventional vehicles, there was 11.2 kg per vehicle.

- Graphite, Nickel, Cobalt, and Lithium are some of the other elements present exclusively in electric vehicles: 66.3 kg per vehicle, 39.9 kg per vehicle, 13.3 kg per vehicle, and 8.9 kg per vehicle.

- Rare earth metal is also present in the composition of 0.5 kg per vehicle.

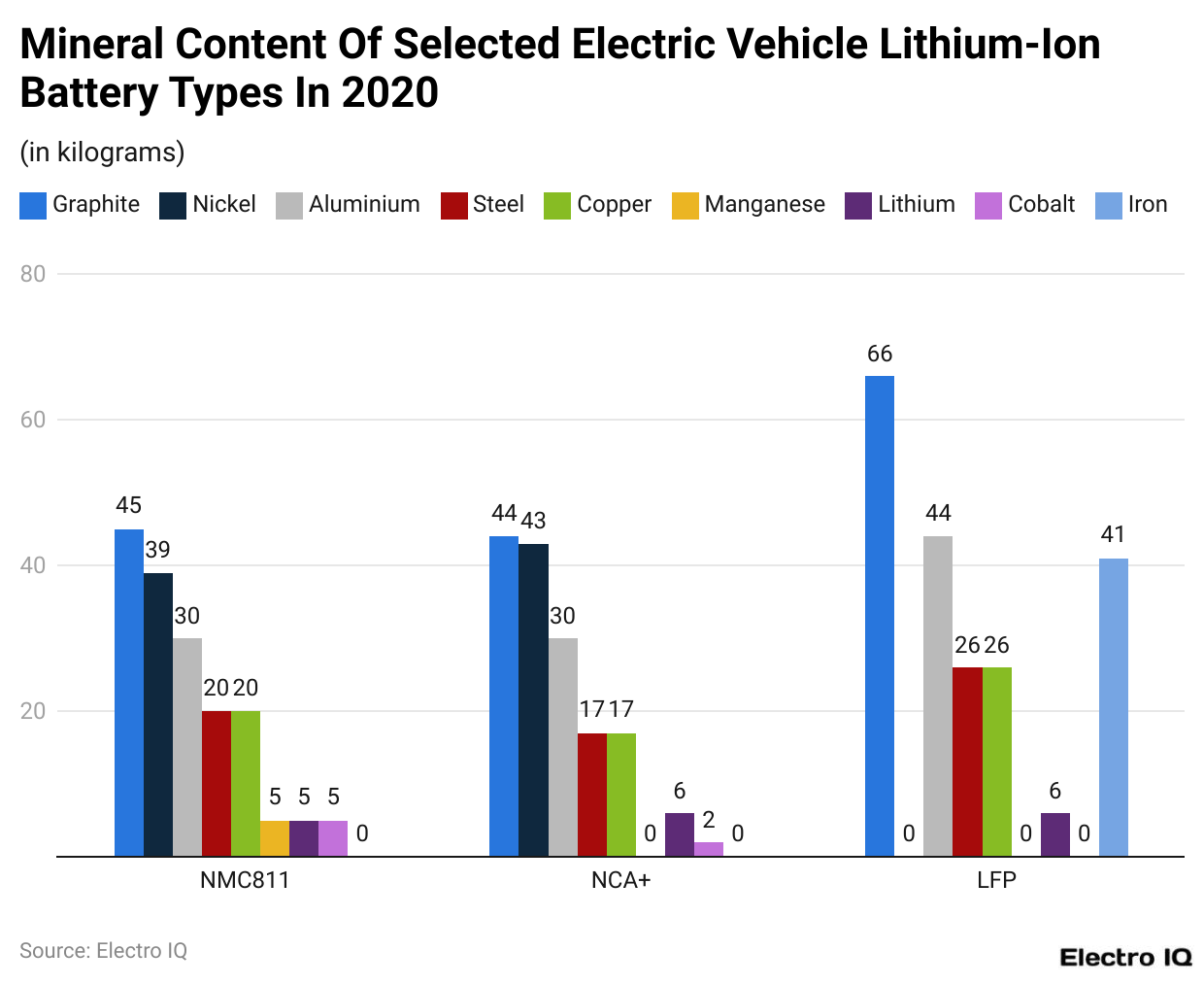

Mineral Content Of EV Lithium-Ion Batteries

(Reference: Statista.com)

- Based on the battery recycling statistics, the mineral content of lithium batteries can be divided into three categories, namely NMC811, NCA+ and LFP.

- The category of NMC811 has the following composition: graphite 45 kg, Nickel 39 kg, Aluminum 30 kg, Steel 20 kg, Copper 20 kg, Lithium 5 kg, Cobalt 5 kg, Iron 0 kg, Manganese 5 kg.

- While NCA+ has shown the following composition: Graphite 44 kg, Nickel 43 kg, Aluminum 30 kg, Steel 17 kg, Copper 17 kg, Lithium 6 kg, Cobalt 2 kg, Iron 0 kg, and Manganese 0 kg.

- Accordingly, LFP has the following composition: Graphite 66 kg, Nickel 0 kg, Aluminum 44 kg, Steel 26 kg, Copper 26 kg, Lithium 6 kg, Cobalt 0 kg, Iron 41 kg, and Manganese 0 kg.

Lithium-Ion Battery Requirement By Region

(Reference: Statista.com)

- Battery recycling statistics reveal that the lithium-ion requirement for electric vehicles has increased significantly. This can be classified into four regions: China, Europe, the United States, and the remaining countries.

- China consistently has the highest lithium-ion demand in the world.

- In 2016, the Lithium-ion demand in China was 30.3 gigawatt-hours, followed by the United States with 6.2 gigawatt-hours, then Europe with 4.8 gigawatt-hours, and finally, the remaining countries with 2.5 gigawatt-hours, making the total global demand for electric vehicles 43.8-gigawatt hours.

- By the end of 2023, China’s demand for lithium-ion batteries was 400 gigawatt-hours, followed by Europe’s demand of 200 gigawatt-hours and the United States and other regions’ demand of 100 gigawatt-hours each.

Demand For Selected Minerals For EV Production

(Reference: Statista.com)

- The electric vehicle industry has witnessed significant growth in recent years, and it is expected that this growth will continue to flourish in the automotive industry.

- The battery recycling statistics show that in 2020, graphite had the highest demand in the industry, with 141 metric tons.

- By 2030, graphite is predicted to have the highest demand, at 2,499.3 metric tons, followed by copper, at 1,632.6 metric tons.

- In 2040, the electric vehicle industry will need 441.1 metric tons of cobalt, 859.3 metric tons of lithium, 3,119.4 metric tons of copper, 3,286.7 metric tons of nickel, and 3,568.5 metric tons of graphite.

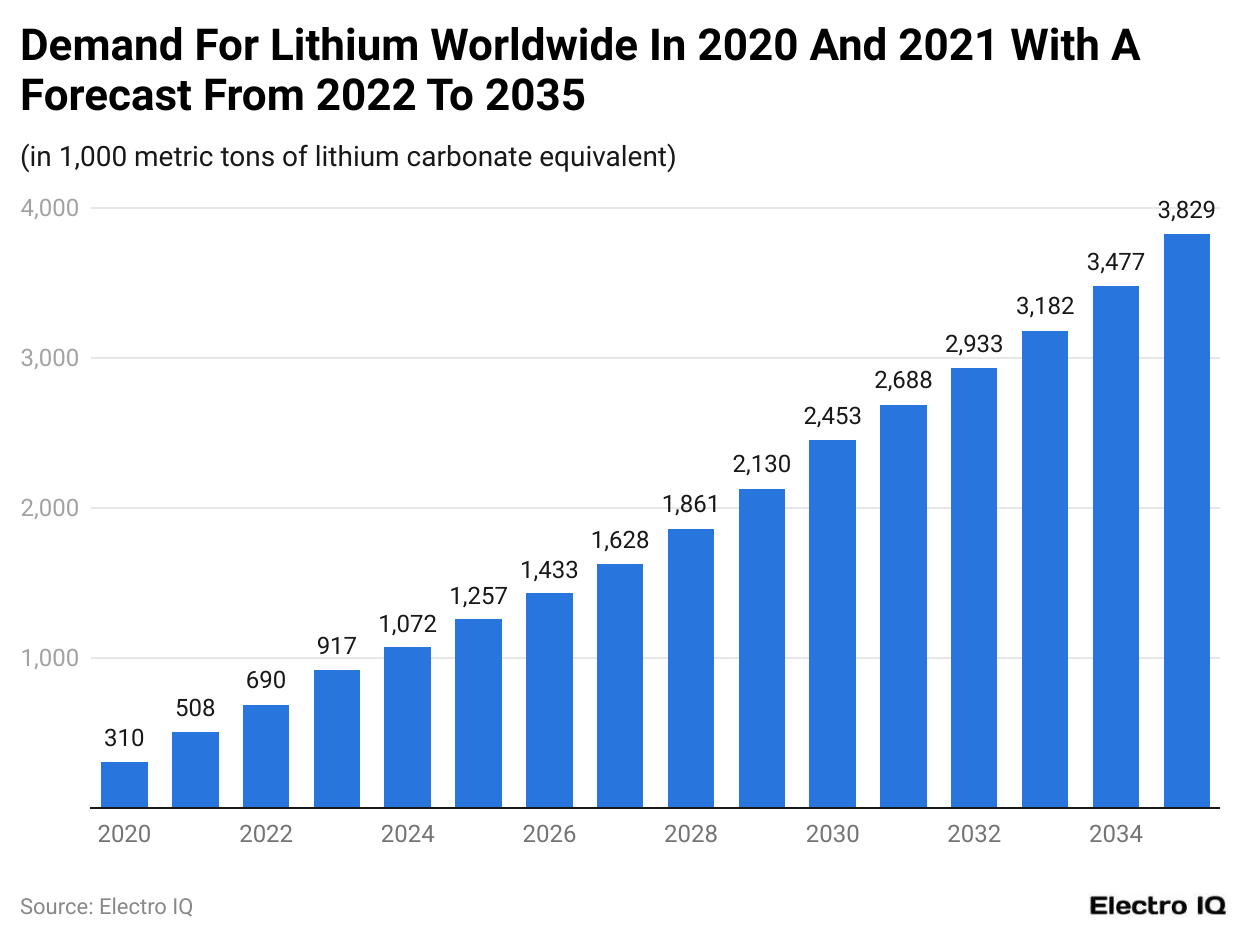

Rising Lithium Demand

(Reference: Statista.com)

- Based on the battery recycling statistics, lithium-ion is becoming increasingly necessary worldwide.

- As of 2023, the lithium requirement is 917k metric tons.

- The global lithium requirement is forecasted to be 3,829k metric tons by the end of 2035.

Rise Of Electric Vehicle Battery Recycling

(Reference: Statista.com)

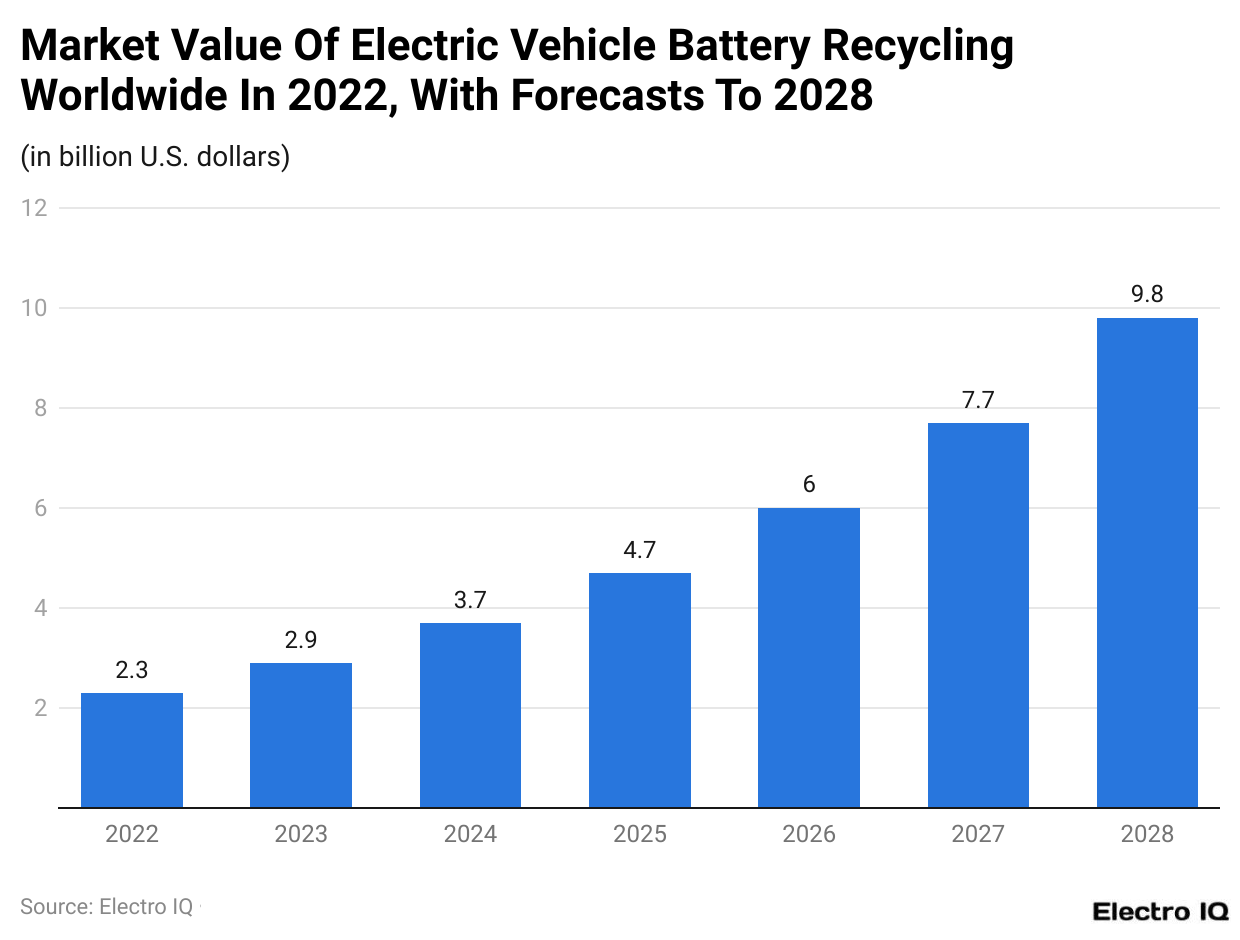

- The battery recycling statistics showcase the rise in the market value of electric vehicle battery recycling worldwide.

- In 2023, the market value of the electric vehicle recycling industry was $3.7 billion.

- It is estimated that the market value of electric vehicle battery recycling worldwide will be $9.8 billion by the end of 2028.

Worldwide Lithium-ion Battery Recycling Market Value

(Reference: Statista.com)

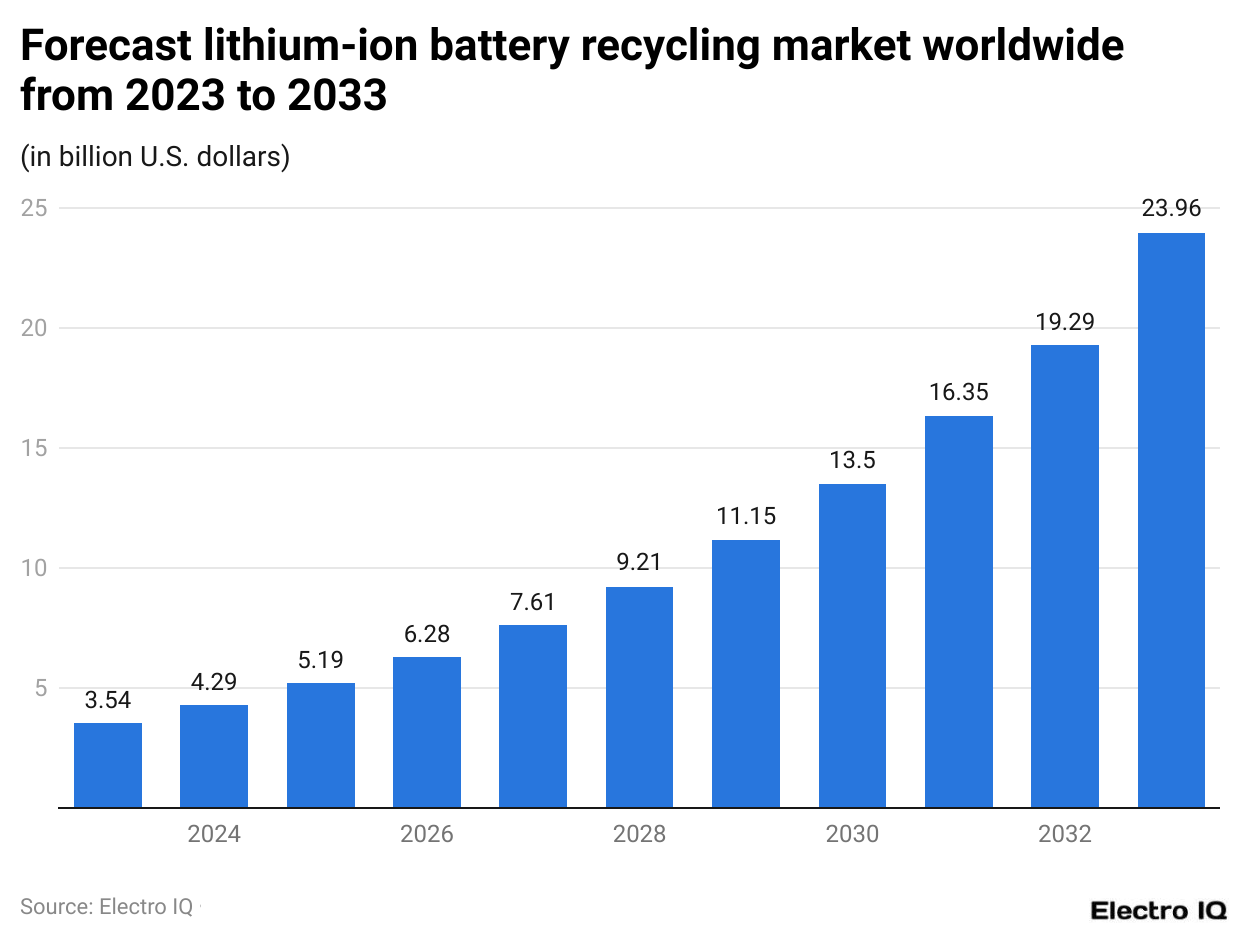

- Lithium-ion battery recycling is a booming market that is expected to showcase unprecedented growth in the coming years.

- According to battery recycling statistics for 2023, the lithium-ion battery recycling market is $3.54 billion.

- By the end of 2033, the lithium-ion battery market is projected to reach $23.96 billion.

Lithium Ion Battery Requirement By Segment

(Reference: Statista.com)

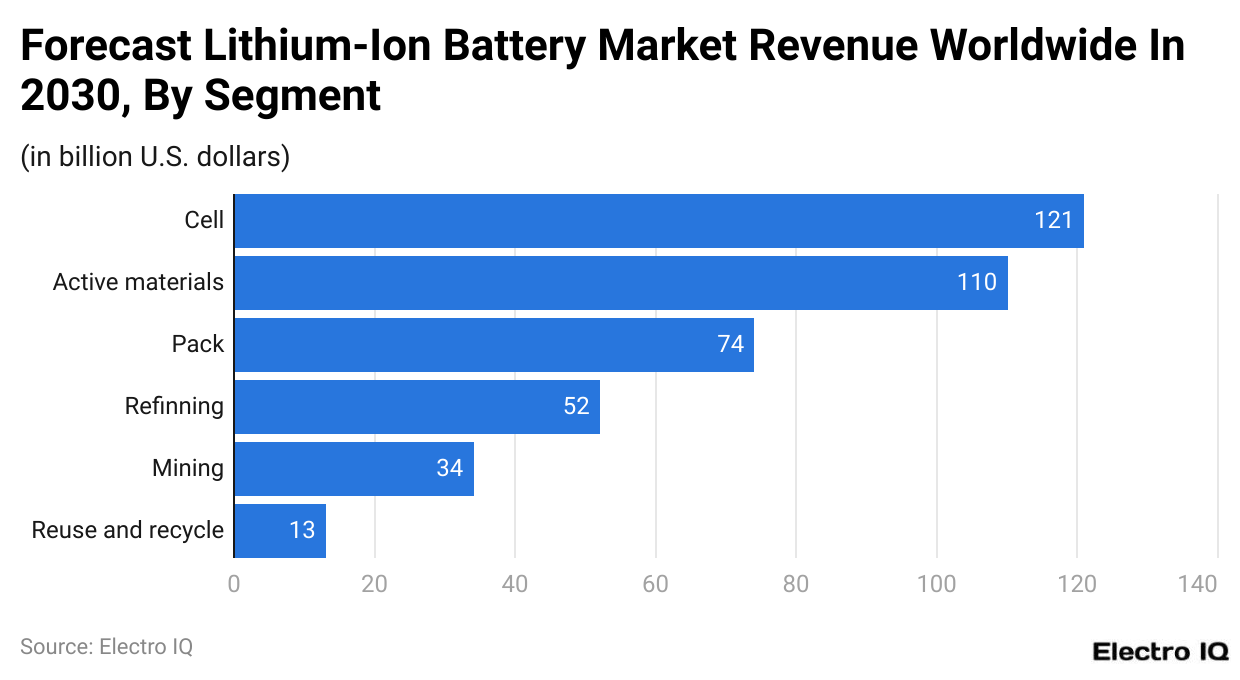

- The battery recycling statistics show that the lithium-ion battery market is expected to grow; however, it would be interesting to witness the industry’s growth in different categories.

- The lithium-ion battery market can be classified into the following categories: Cell, Active materials, Pack, Refining, Mining, Reuse, and recycle.

- By the end of 2030, it is predicted that the market revenue of lithium-ion batteries will be as follows:: Cell, $121 billion; Active materials, $110 billion; Pack, $74 billion; Refining, $52 billion; Mining, $34 billion; Reuse and recycle, $13 billion.

Lithium Ion Reuse Future By Country

(Reference: Statista.com)

- Reusing lithium-ion batteries is a crucial component of battery recycling statistics; hence, it is essential to have information about it.

- China will have the highest revenue opportunity by the end of 2030, with lithium-ion usage at $6 billion.

- It is followed by Europe, the US, and the rest of the world with $3 billion, $2 billion and $2 billion.

Estimated Recovery Rate Of Battery Minerals

(Reference: Statista.com)

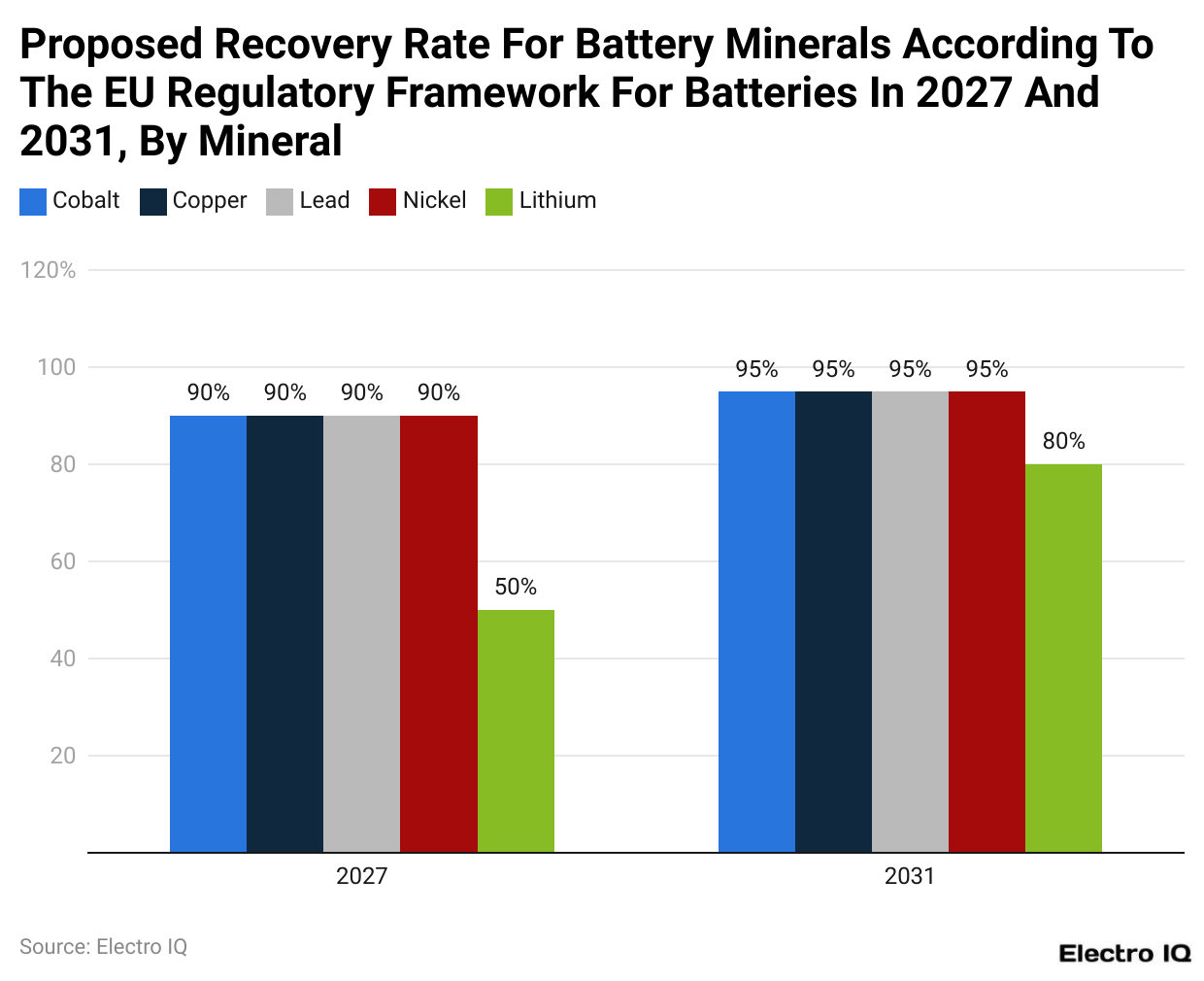

- For environmental sustainability, it is essential to have a high battery recovery rate.

- The EU regulatory framework provides an adequate target to be achieved before the deadline.

- Based on battery recycling statistics, the proposed recovery rate in 2027 is Cobalt with 90%, Copper with 90% Lead with 90%, Nickel with 90% Lithium with 90%.

- By the end of 2031, the technologies involving the recovery of battery minerals are expected to improve significantly with the following rate: Cobalt at 95%, Copper with 95% Lead with 95%, Nickel at 95%, and Lithium at 85%%.

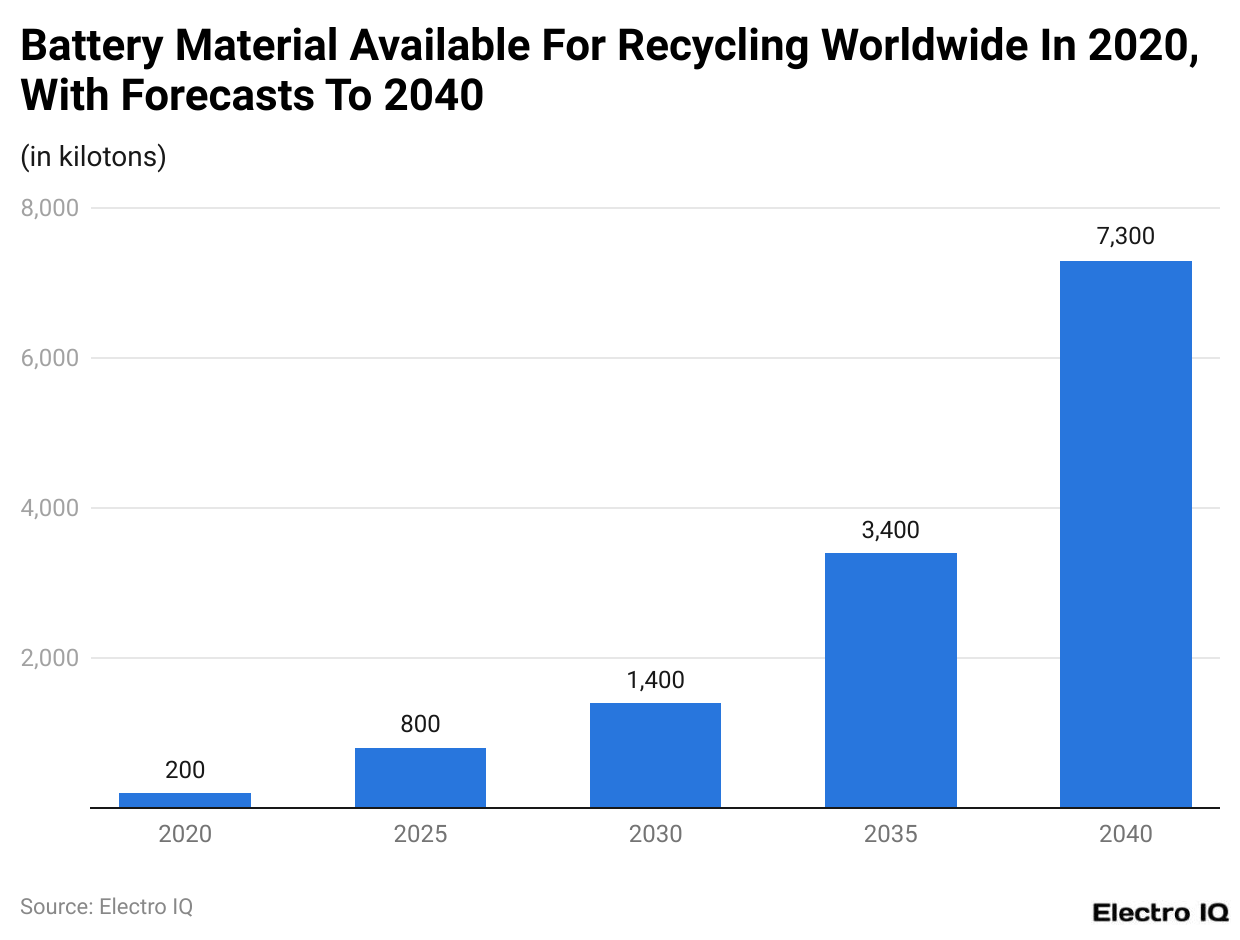

Battery Recycling Material Availability

(Reference: Statista.com)

- The battery recycling statistics show that there will be an increase in battery material availability in the coming years.

- In 2020, the battery material availability was 200 kiloton.

- It is predicted that the availability will be 800 kilotons by 2025, increasing to 1400 kilotons by 2030. By 2035, the availability will be 3400 kilotons and by the end of 2040, it will be a gigantic 7300 kilotons.

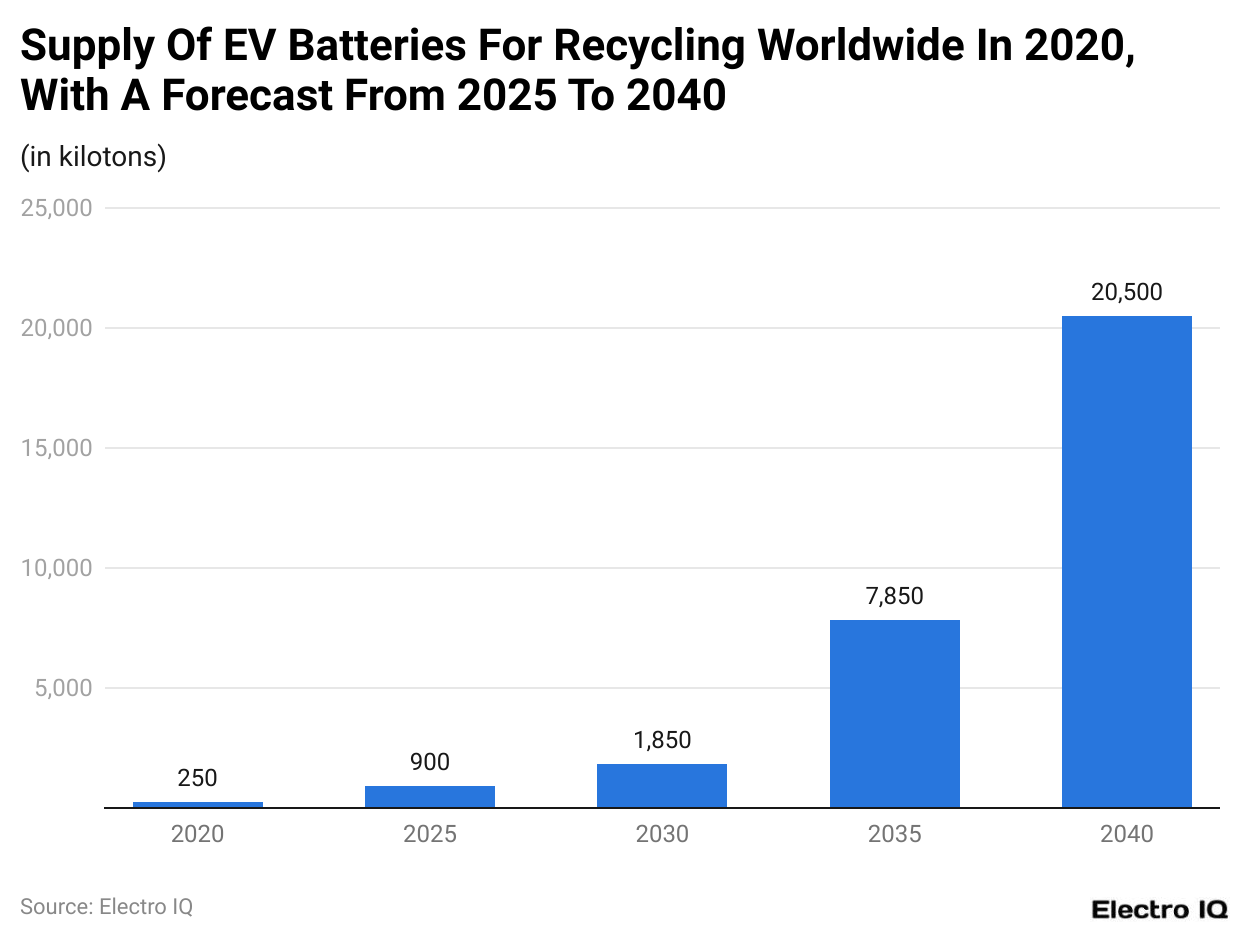

Supply Of Electric Vehicle Batteries For Recycling

(Reference: Statista.com)

- The battery recycling statistics display a significant increase in the supply of EV batteries over time.

- In 2020, the supply of EV batteries was 250 kilotons.

- It is predicted that the availability will be 900 kilotons by 2025, increasing to 1850 kilotons by 2030. By 2035, it will be 7850 kilotons, and by the end of 2040, it will be a gigantic 20500 kilotons.

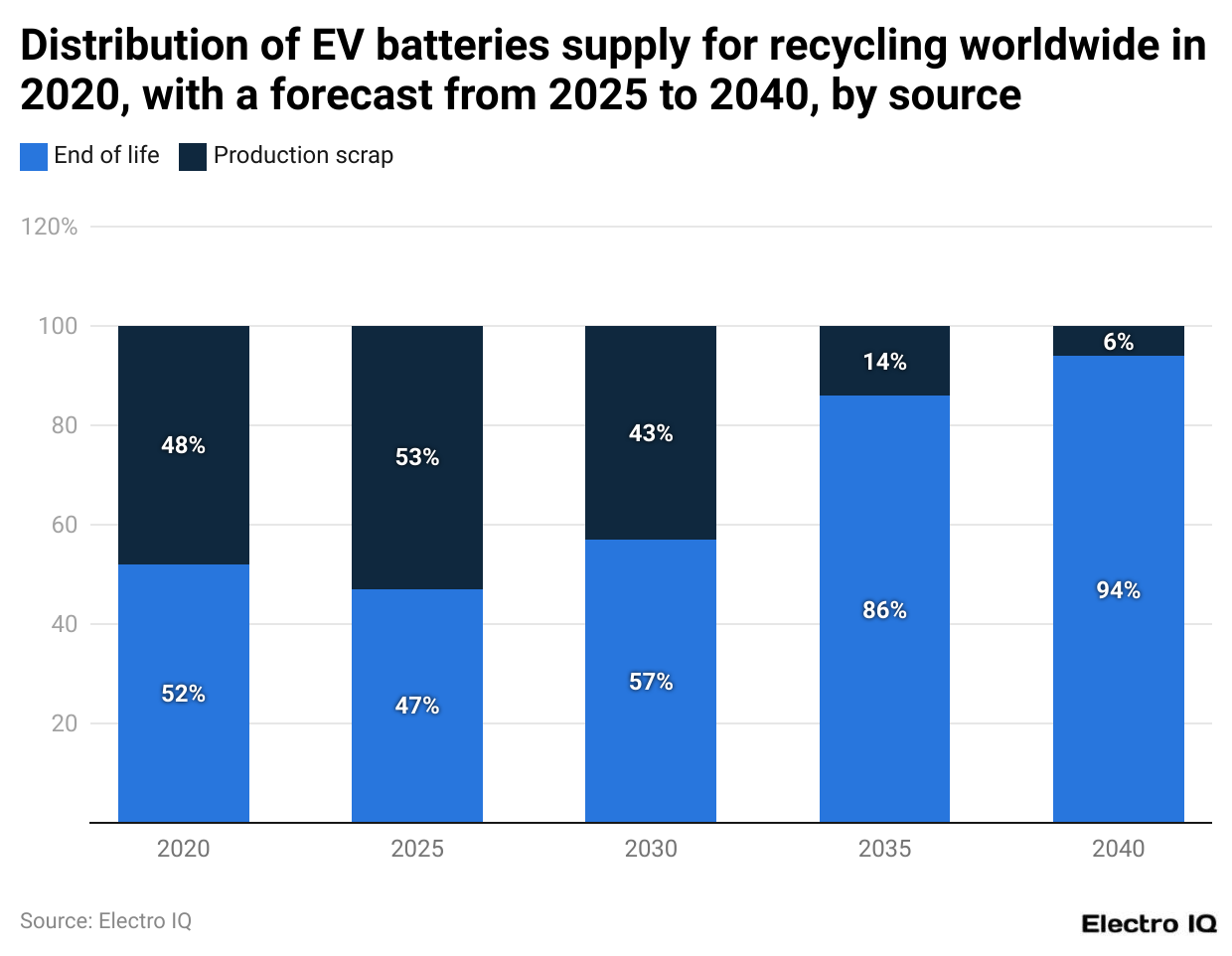

Distribution Of EV Battery Recycling By Source

(Reference: Statista.com)

- An essential aspect of studying and learning about Battery recycling statistics is the overall distribution of electric vehicles of battery by their source.

- In 2020, the composition of EV batteries will be evenly matched, with 52% end-of-life and 48% production scrap.

- It is predicted that in coming years, the end-of-life battery source share in EV battery supply will increase, and, accordingly, production scrap will decrease. This is shown by predictions that EV battery supply will increase to 47% in 2025, 57% in 2030, 86% in 2035, and 94% by the end of 2040.

- In contrast, scrap production is expected to decrease by 53% in 2025, 43% in 2030, 14% in 2035, and only 6% by the end of 2040.

Battery Recycling Overview

According to battery recycling statistics, lead-acid batteries have the most significant recycling rate of any battery type, with over 95% of these batteries recycled in 2023. The long-standing, well-established lead-acid battery recycling procedures that have been in place for decades are to blame for this high recycling rate. In comparison, the recycling rate of lithium-ion batteries is projected to be just 25% in 2023 despite their increasing significance. Nonetheless, it is anticipated that by 2024, this percentage will rise to 30% as improved recycling techniques are encouraged by growing regulatory pressure and technological improvements in the recycling field.

An essential component of establishing an eco-friendly and sustainable economy is the recycling of batteries. The battery recycling industry was estimated to be worth US$13.7 billion globally in 2023. This market is anticipated to expand rapidly, with a projected value of US$17.4 billion by 2024. The need for batteries, particularly lithium-ion batteries used in energy storage systems, consumer electronics, and electric vehicles (EVs), is fuelling the increase.

According to the regional study of Battery Recycling Statistics, Europe is a market leader, holding close to 40% of the worldwide market share for battery recycling in 2023. Large-scale recycling facilities and stringent environmental restrictions are to blame for this supremacy. North America comes second with a 25% market share, propelled by rising electric car sales and robust government backing for recycling programs. The Asia-Pacific area is another essential participant, with China in particular fast increasing its recycling capacity to handle the increasing amount of battery trash.

The recycling of batteries has a significant economic impact. Over 100,000 people were employed worldwide by this industry in 2023, and it made an essential economic contribution to local communities. With the industry growing, employment is predicted to reach 120,000 by 2024. Recycling has clear financial benefits since it may be profitable for enterprises in the sector because precious elements like lithium, cobalt, and nickel can be recovered and used to offset the expenses of the recycling process.

Conclusion

Battery recycling is emerging as a crucial part of environmental sustainability. Along with this, the rising energy demand from various countries has led to the booming of the battery recycling industry. The battery recycling statistics show how the rise in battery recycling can lead to increased impactful demand for various electric products such as electric vehicles.

As the technology regarding battery production, mineral enrichment and battery usage is expected to grow, this industry will flourish accordingly. With rising concerns about climate change, abundant economic opportunities are available for the battery recycling industry.

Sources

FAQ.

The recycling rate for lithium-ion batteries is projected to be 25% in 2023, expected to rise to 30% by 2024.

Europe leads with a 40% market share and North America at 25%.

The global battery recycling market is expected to reach $17.4 billion by 2024.

Pramod Pawar brings over a decade of SEO expertise to his role as the co-founder of 11Press and Prudour Market Research firm. A B.E. IT graduate from Shivaji University, Pramod has honed his skills in analyzing and writing about statistics pertinent to technology and science. His deep understanding of digital strategies enhances the impactful insights he provides through his work. Outside of his professional endeavors, Pramod enjoys playing cricket and delving into books across various genres, enriching his knowledge and staying inspired. His diverse experiences and interests fuel his innovative approach to statistical research and content creation.